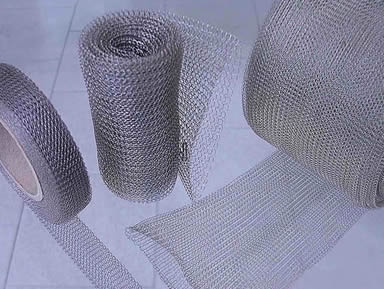

Knitted Mesh

Knitting is a method for making cloth from threads or yarns. For industrial and commercial applications, knitted material utilizes a much broader range of materials and involves a wide range of post-knitting processes.

The method used to knit wire is similar to that of a knitting machine used to make jumpers and scarves, just on a much larger industrial scale. The form of the final product is generally a long sock, and the structure of the knit, inter-connecting loops of wire/fibres, provides a material with unique properties and application suitability. We can produce a vast array of multi-filament, co-knit, and multi-strand knitted wire meshes. For example, knitted wire mesh with head 10 needles/12 needles, 0.20 mm/0.25 mm diameter wire, mesh dia. 5 mm/12 mm.

Knitted wire mesh is also called knitted wire or knitted mesh, Knotted mesh, Knotted wire, Knotted wire mesh, Chain mesh, Wire net, Wire netting, Silt mesh, Mesh stocking, Wire mesh stocking, Sock mesh, Stretchy mesh, Holey mesh, Mesh ribbon, Chicken wire, Metal bag, Knitted copper, Interwoven metal, Interlocked wire, Wire protector and Wine bottle mesh.

Almost any material that can be drawn into a wire or filament can be used to produce a knitted mesh. Round wires from 0.11mm to 0.35mm diameter are most commonly knitted, but for special applications it is possible to knit wire as small as 0.03mm or as large as 0.8mm in diameter.

Knitted Wire mesh is made from knitting of various wire materials including stainless steel, copper, synthetic fiber and other materials.

Main Materials Applied for Knitted Mesh:

Monel knitted wire mesh has good corrosion resistance in all extreme environments and it is reasonably conductive and is tough with high tensile strength, giving good wear characteristics.

Knitted wire mesh made of tinned copper clad steel has the best shielding performance of all wires used in knitted meshes, combining low contact resistance with a small degree of permeability. It is not suitable for highly abrasive applications where the TIN plating may wear away to expose the copper. The corrosion resistance of tinned copper clad steel knitted wire mesh is suitable for most applications.

Aluminum knitted wire mesh is mechanically weak and will readily take a compression set and this combined with its readiness to form a non-conducting oxide. Stainless steel knitted mesh is often used as a protective final layer over the other knitted mesh gasket, materials on order to provide a wear-resistant contact surface. Aluminium knitted mesh is for numerous aerospace, military and nuclear applications

Post-knit processing of knitted wire mesh is an important step in transforming the knitted material into knitted wire products. There are a variety of post-knitting processes methods as below:

- Coiling, Folding & Layering Knitted Wire Mesh.

- Crimped Knitted Wire Mesh.

- Die-Pressing Knitted Wire Mesh.

- Spiraling & Milling Knitted Wire Mesh.

- Cleaning.

- Inspection of Knitted Wire Mesh.

Application: Knitted wire mesh products are applied to those applications including cryogenic, high temperature, corrosive atmosphere, heat conductive, high usage, or special service applications.

E-mail: sales@yaqiwiremesh.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.